OnRobot Eyes – adding vision ...

Flexible and easy to deploy 2.5D vision system for robotic applications. With…

Now, packaging can be done even faster and without the employees suffering physical strain. Plus Pack reaps the benefits of an improved working environment and a significant boost in productivity after selecting OnRobot’s End-of-Arm tools, which can be adjusted to each specific order rolling in from Plus Pack’s customers.

For several generations, Plus Pack has been at the head of the pack among producers of food packaging. The company has continually developed new products that are more or less environmentally friendly, having received several international awards for this work. And not only the green revolution, but also the working environment for their more than 200 employees is given high priority by the company. The working environment in particular is one of the reasons for focusing on automation. It is used particularly where heavy and monotone tasks can be taken from the employees to be done by collaborative robots, says strategic project manager Bastian Fietje: »The work station where we use the gripping arm from OnRobot replaces a packaging process where the operator used to work manually on stacking products on top of each other, pressing out the air between them. The manual process required a lot of repeated heavy lifting and a lot of stress on the shoulders. We have removed this physical strain from the employees,« he says.

Unproblematic solution:

And certainly, there is no reason to wait before automating the production. At Plus Pack, the implementation of the End-of-Arm tool from OnRobot has been fast and unproblematic, says project manager Simon Laigaard: »In our opinion, the OnRobot gripping arm is easy to work with. By adjusting four screws, we can change the fingertips on the gripping arm, making it precisely suited for the individual product. If we had opted for building separate tools for each product, the cost would have been significantly higher than with this solution, where the gripping arm is easily adjustable.

We ran some tests with the gripping arm in the lab, and the programming was done in a few days. After that, it took just 30 minutes to implement the gripping arm at full speed in the packaging line,« he says.

A definite recommendation of OnRobot:

As stated, one of the reasons to use collaborative robots is the working environment. Another reason is productivity, which becomes very flexible by using gripping arms from OnRobot, says Bastian Fietje: »We manufacture a lot of different products, and we have a lot of different customers, for whom we manufacture customized packaging solutions. For this reason, we are always trying to optimize the products and the packaging process for each customer, which is something OnRobot’s End-of-Arm tools help us do.

If you are planning to automate your production, I would definitely recommend gripping arms from OnRobot, as they offer the flexibility to create customized solutions suitable for specific needs. This is something we have never seen from other suppliers of End-of-Arm tools, he said.

Flexible and easy to deploy 2.5D vision system for robotic applications. With…

The OnRobot Soft Gripper is able to pick a wide array of…

Two collaborative robots (cobots) fitted with four grippers from OnRobot are assisting…

Automation is growing faster and faster in Asia and Oceania. OnRobot’s One…

_Flexible production – large-stroke optimizes CNC lathe-tending for multiple part sizes with…

_Compact, lightweight Gecko Single Pad Gripper requires no cables, electricity, air, or…

This video demonstrates how the 3FG15 is ideal for gripping a wide…

The Gecko Single Pad (SP) Gripper brings the innovative Gecko adhesive gripper…

Osvald Jensen talks about RG2 Dual Gripper and how, in a cost…

OnRobot has developed the market’s most versatile, user friendly and safe collaborative…

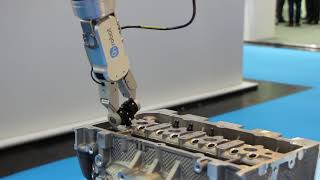

PCB handling

Quick Guide Manual – Easy start-up with the RG2 Collaborative Gripper

The Dual RG2 is used at Grenaa’s high mix low volume production…

Tiama Hot Lab

Gripper intelligence – Showing some of the feedback you can get from…

OnRobot Dual Gripper and HEX sensor Block Stacking Application by Olympus Technologies

Usage of the OnRobot Gripper with and without Depth Compensation

Automate Packaging – OnRobot Collaborative Grippers Pack Delicate Herbs at Rosborg Greenhouse

The Gecko Gripper uses the same adhesive system for gripping as the…

OnRobot HEX Clutch Insertion Application at Automatica 2018

Adding a force-torque sensor to your robot makes it easy to teach…

OnRobot HEX Polishing Application at Automatica 2018

Electronic Assembly with our collaborative application. Ram Insertion with OnRobot Force/Torque sensor…

Easy hand guiding on KUKA with OnRobot Force/Torque sensor

Pick and place different sizes of chips with OnRobot RG2 combined with…

OnRobot RG2 Dual Gripper Application at Automatica 2018

OnRobot RG2-FT is a new version of the RG series with integrated…

OnRobot RG2-FT Intelligent Gripping Application at Automatica 2018

OnRobot RG6 Pick and Place Application at Automatica 2018

OnRobot showcased during IMTS 2018 its End-of-Arm Tooling in a wide range…

To meet the growing market demand, FT-Produktion turned to specialised robot technology…

OnRobot showcased during Automatica 2018 its End-of-Arm Tooling in a wide range…

The Gecko Gripper’s origins are found in nature and space. Inspired by…

With technology inspired by nature, the Gecko Gripper makes it possible to…

RG2-FT – the first gripper in the world with built-in intelligence and…

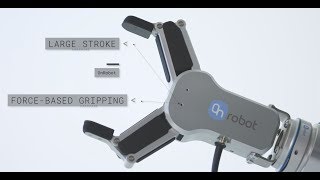

RG2 and RG6 – Plug & Produce grippers for multiple purposes. Designed…

VG10 is a flexible, adjustable, electrical vacuum gripper. The gripper features a…

Dual gripper speeds cycle time and can improve productivity by 50% or…

Out-of-the-box deployment—plug into the robot arm and pinch the gripper to fit…

At Hannover Messe 2019 we’ve had robots from Kawasaki Robotics, Universal Robots…

At Hannover Messe 2019 we’ve had robots from Kawasaki Robotics, Universal Robots…

We spotted our end-of-arm tools on a number of other stands at…

At Autmate 2019 we hosted a very popular cocktail party at our…

Compact, highly customizable electric vacuum gripper for all your needs.

OnRobot Collaborative Applications at iREX, Japan 2019

Since the OnRobot VG10 electric vacuum gripper doesn’t require any external compressor…

OnRobot 6-axis force torque sensors provide accurate force and torque measurements along…

OnRobot Takes Robot Compatibility to the Next Level with the OnRobot One-System…

OnRobot CEE Partner Event, Warsaw, September 2019

We asked two of our colleagues to compete – Who can be…

Tomenson, a family-owned manufacturer of world-leading hydraulic manifolds, is focused on continuous…

within 7 work days

for all EU orders

discount for next purchase