The power and importance of unique sensing technologies

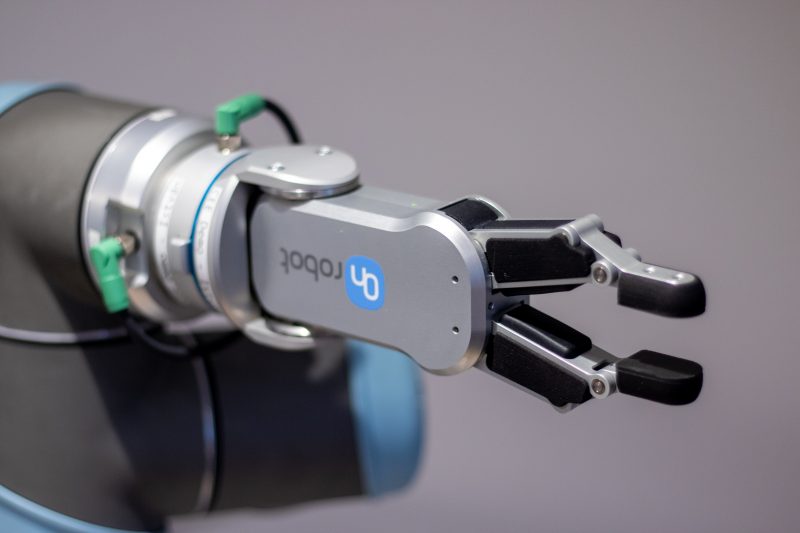

Sensing technologies enable force control, equipping the robot to place and fit objects precisely.

The process of circuit board assembly needed automation. HEX sensor is the answer.

Ever since radio and television became an integral part of everyday life, perhaps even earlier, the circuit board assembly has been one of the standard electronic production processes. Parts of this process have been automated right from the start, but complex assembly actions, especially the handling of sensitive materials, have been carried out by the human hand. In other words, the producers of highly sensitive electronics, such as those used to make smart phones, remain dependent on the sensitivity of human hands.

One example is the countless online tutorials on YouTube showing end users how to install a DDR4 RAM module on the motherboard of their computer. Close attention is required to find the ideal point for installation, then the module must be moved slightly side to side before it finally can be pressed home so that a gentle “click” can be heard and felt. Unlike human beings, until now, they have never been able to apply a gentle sensing pressure!

Yet now, thanks to onRobot sensor specialists, industrial robots can be provided with the required sense of touch with HEX sensor in just a few minutes and without costly, time-consuming programming. Among the many preprogrammed solutions which end-users can simply configure is the fully automatic circuit board assembly, such as the installation of DDR4 memory modules.

To do this, the robot is shown the path once by hand, so that it can optimally mimic the assembly action of a human hand. The second part of this process is where the provision of the robot arm, with a sense of touch, is essential, as it then mounts the module precisely on the board using the required force, and senses when the RAM module latches into place. Conversely, using the same sensitivity, it can then open the sensitive clip holding the RAM and remove the module from the circuit board.

Even in a structured production environment, this represents a highly exciting new automation possibility. Thanks to the tactile HEX sensor, this process can also be automated in unstructured production situations. This is because with your help, robots can even “find” objects in different locations and correct the saved path as necessary.

Whether boards are single or double-sided, or whether they are produced as single cards, small series runs or using THT, mixed or SMD assembly, robots with HEX sensor can automatically adapt to their production environment and the individual requirements of the user. In the global price/performance battle, tactile sensors offer companies lucrative new options for increasing their production output while at the same time maintaining stable quality and reducing production costs.

Thanks to the preprogrammed software package, the costs for such an automation solution are affordable even for small companies, because for the first time, an expert-implemented, time-intensive and costly installation process is no longer necessary. The robots, for example from Universal Robots or KUKA, are ready for use within minutes and can enter service immediately. Even during the first year, total savings for companies can reach 100,000 euros.

Sensing technologies enable force control, equipping the robot to place and fit objects precisely.

In addition to specific new automation capabilities, a sense of touch in robots can also represent a strategic advantage for companies.

In order to grant competitive advantages, industrial robots must become sensitive and smart.

special adhesive technology with no-mark gripping inspired by nature

5,385.00€

Low Deformation sensor - giving the sense of touch to your robot

2,960.00€

High Precision force-torque sensor - giving the sense of touch to your robot

2,960.00€

within 7 work days

for all EU orders

discount for next purchase