The power and importance of unique sensing technologies

Sensing technologies enable force control, equipping the robot to place and fit objects precisely.

There’s little doubt that robotic surface finishing and other maturing technologies are revolutionizing manufacturing.

As the president of the International Federation of Robotics (IRF), Junji Tsuda, puts it: “Industrial robots are a crucial part of the progress of manufacturing industry. Robots evolve with many cutting-edge technologies. They are vision recognition, skill learning, failure prediction utilizing AI, new concept of man-machine-collaboration plus easy programming and so on. They will help improve productivity of manufacturing and expand the field of robot application. The IFR outlook shows that in 2021 the annual number of robots supplied to factories around the world will reach about 630,000 units.”

The IFR World Robotics 2018 report also mentions several other trends, including the increasing ease with which robots can be integrated into manufacturing processes using plug and play technology. The report also mentions the growth of “cobots” or collaborative robots that work seamlessly alongside human workers.

This is all well and good, but what does that mean for the average manufacturing company? An example of a manufacturing process that is already benefitting from intelligent automation is surface finishing.

End of Arm Tooling (EOAT) refers to the use of interchangeable tools that can quickly and easily connect to the end of a standard robotic arm. Common examples are grippers that can be used to pick and stack items or sensors to locate items or check physical properties.

Surface finishing relies on a combination of an end-of-arm tool and sensor. Just as the finish of a hand-made product may depend on the expertise of a master-craftsman, so the quality of a robotically finished item relies on precision sensors and well-designed tools. Well-designed and accurate end-of-arm tools are arguably more important than the robotic arm itself.

OnRobot has developed a 6-axis Force Torque (F/T) Sensor that precisely measures both lateral forces and the torque in X,Y and Z directions. Optical force sensor photodiodes are used to measure the amount of reflected light emitted by an LED. The measured values are compared, which leads to accurate force and torque measurements.

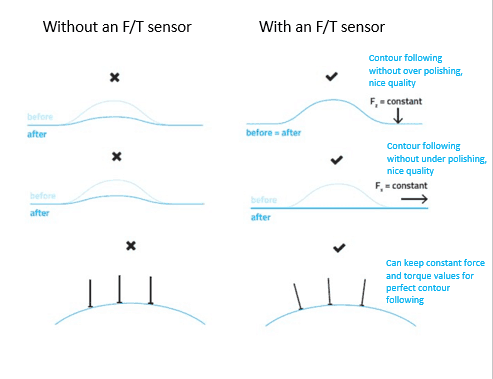

Precise force measurements are crucial for high-quality robotic surface finishing. A constant force is applied to the surface of the item throughout finishing, which means that the finishing tool follows the surface contours.

There are numerous applications for accurate robotic surface finishing. Most manufacturing materials require surface finishing and robotic tools combined with 6-axis sensors are ideal for the job.

Applications include:

Manufacturing companies are under pressure to find new and innovative ways to increase productivity, without compromising on quality. Automated surface finishing using end-of-arm tooling and a 6-axis sensor ticks both of these boxes. OnRobot provides a cost-effective way to achieve any desired surface finish, quickly and accurately.

Sensing technologies enable force control, equipping the robot to place and fit objects precisely.

Haptic force/torque sensors offer companies the opportunity to increase their production efficiency in many areas of application to a significant degree.

In addition to specific new automation capabilities, a sense of touch in robots can also represent a strategic advantage for companies.

High Precision force-torque sensor - giving the sense of touch to your robot

2,960.00€

within 7 work days

for all EU orders

discount for next purchase