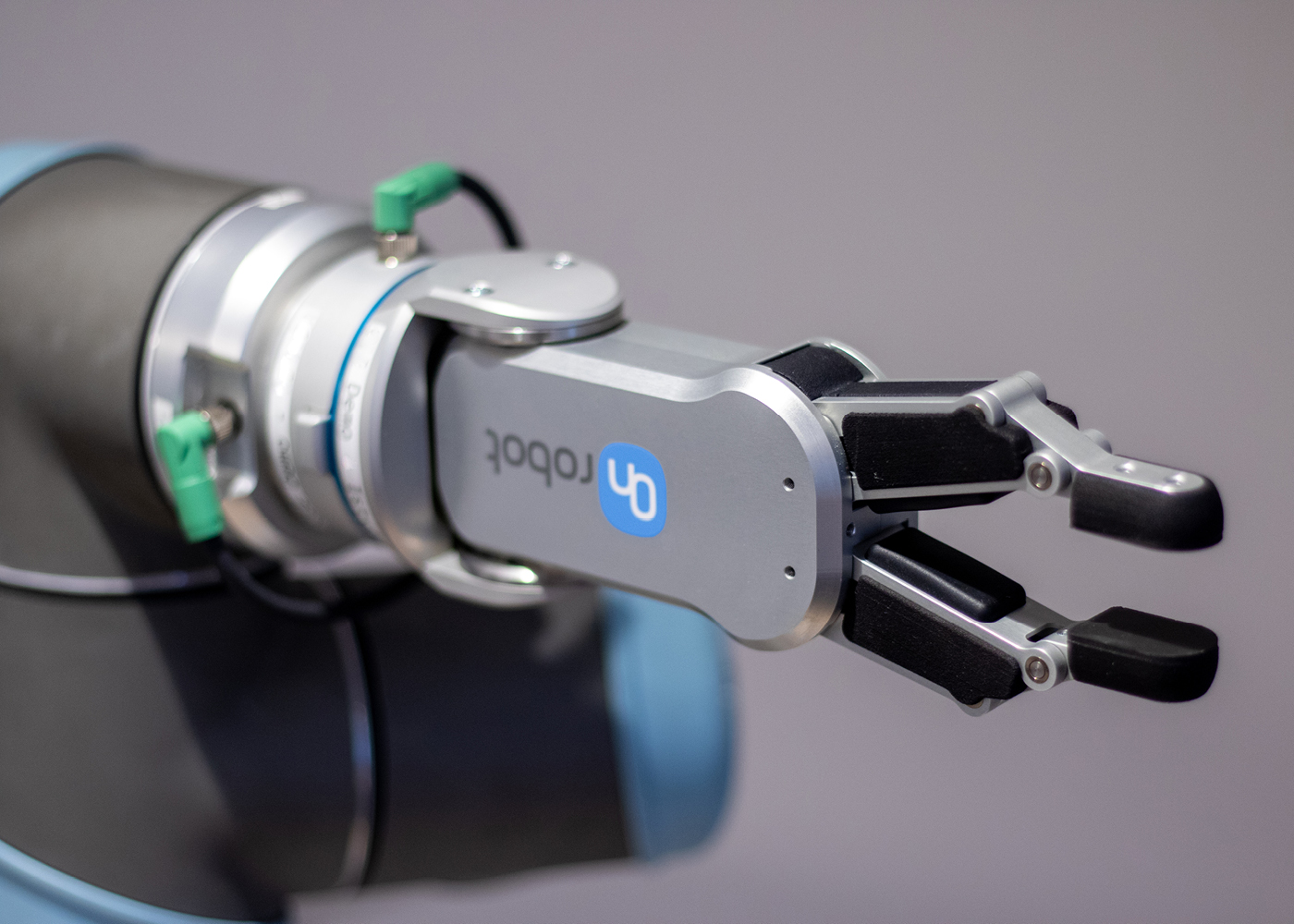

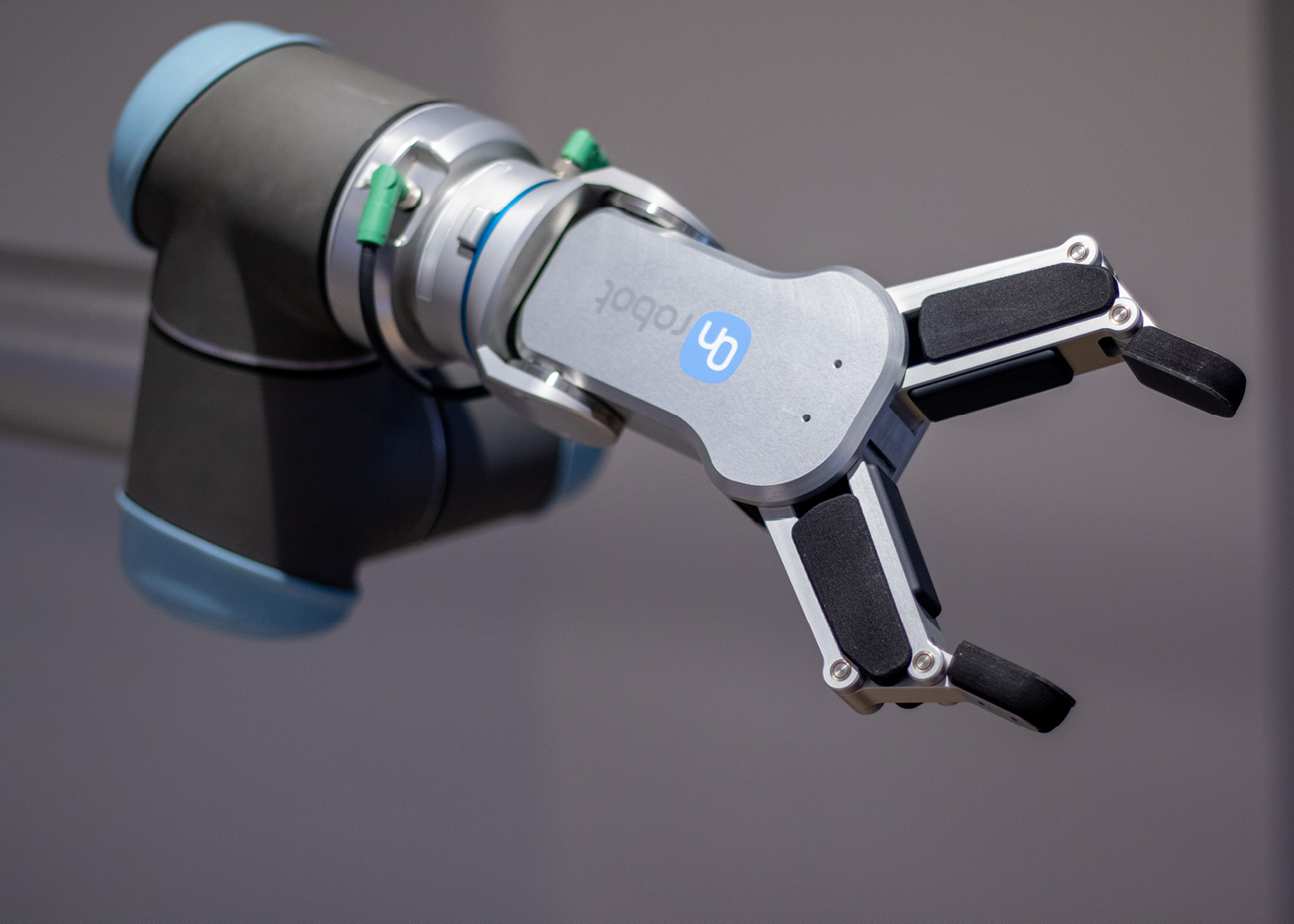

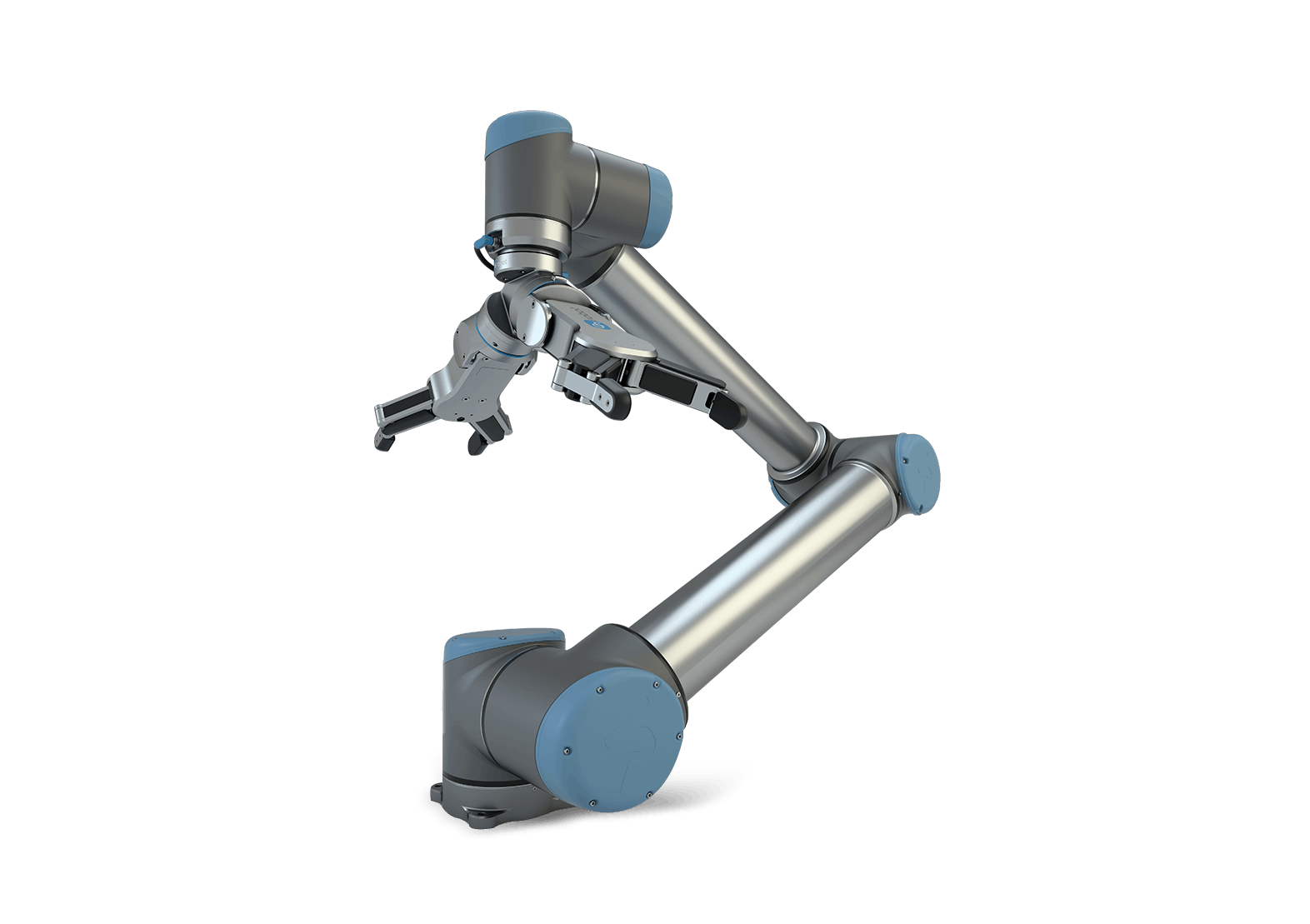

RG2 gripper

2kg payload flexible 2 finger robot gripper with wide stroke

The RG2 gripper – 2kg payload robot arm gripper is a flexible collaborative gripper with built-in Quick Changer up to 110mm stroke. It provides intelligence, fast deployment, easy customization and programming. The outstanding software features through our one system solution decreasing engineering and manufacturing time significantly. The RG2 gripper is a tool for wide range of applications. Customized fingertips provide great gripping flexibility, customers can use one tool for different parts of the production process maximizing robot utilization. The RG2 works seamlessly with our Dual Quick Changer and any of our other grippers to help you maximize utilization of your robots. RG2 is TÜV certified, comes standard with safety shields.

3,530.00€

Automatic payload calculation

Automatic payload calculations simplify the programming of the RG2 gripper.

Large stroke

Automatically detects the stroke at program start without initialization. The maximum grip stroke of the RG2 is 110 mm (adjustable).

TÜV certified

Both the RG2 gripper and the RG6 gripper are TÜV certified.

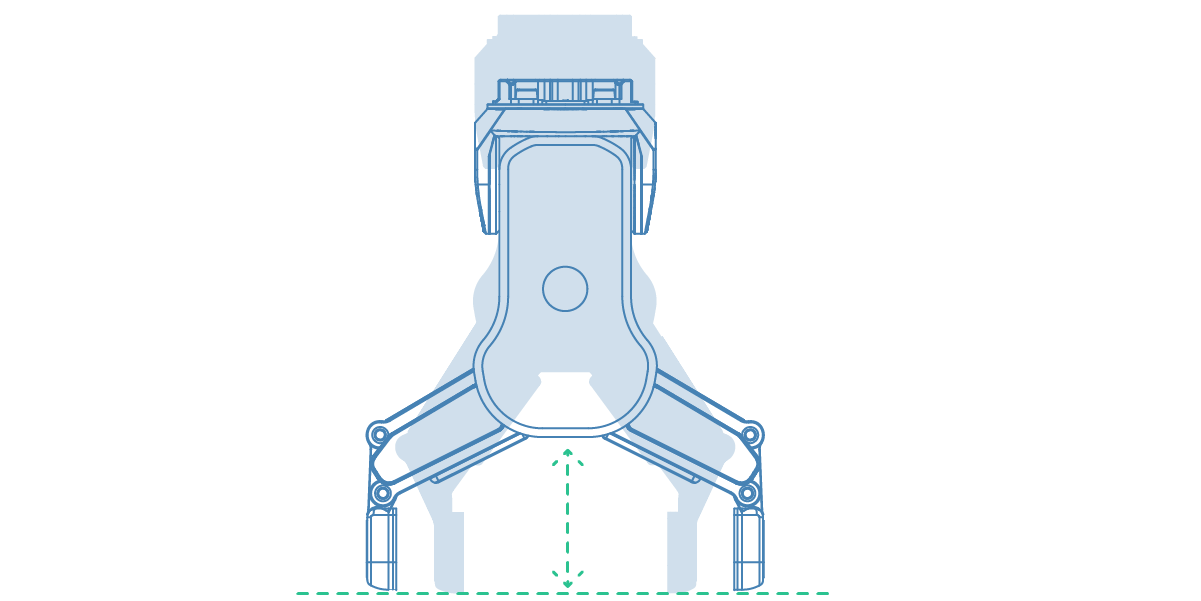

Automatic depth compensation

Automatic depth compensation ensures the gripper’s fingers sweep in parallel across work surfaces.

Automatic tool center point calculation (TCP)

Automatic calculation of TCP eliminates the need for extensive programming in addition to reducing the deployment time.

Grip indications

Automatic “lost grip detection”, “grip detected”, “continuous grip” and “measure width” detections remove the need for manually programming these features.

Integrated software

The gripper comes with pre-integrated software that is easy to install and program, so even employees with no technical background can set it up.

Customizable fingertips

The fingertips of the gripper can be easily customized, fitting the product shape for stable gripping.

OnRobot RG2 and RG6 Grippers

Plug & Produce gripper for multiple purposes. Designed for seamless integration, the RG grippers are ready to work right out of the box. The fast installation and simple programming reduces your deployment time.

Applications

Packaging & Palletizing

Machine Tending

Pick & Place

Robot kit

Essential accessories to make onRobot gripper work with other then UR robots.

615.00€

Compatible robots

Universal Robots

Doosan

Fanuc

Hanwha

Kawasaki robotics

KUKA

Nachi

TM Robot

Yaskawa

Features

Automatic depth compensation

Robot arm moves while fingers stay at the same relative position from object. This feature dramatically simplify programming and avoids time extensive workaround.

Easy deployment

Easy deployment with out-of-the box grippers reduces programming time by 70%.

Plug & Produce

Plug & Produce design reduces deployment time from a day to an hour.

Technical specification

General Properties

IP Classification

IP54

Motor

Integrated, electric BLDC

Adjustable bracket tilting accuracy

°

Gripping time

minimun 0.06 maximum 0.21 s

Gripping speed

minimun 38 maximum 127 mm/s

Gripping force deviation

typical ±25 %

Gripping force (adjustable)

minimun 3 maximum 40 N

Reversing backlash

minimun 0.1 maximum 0.3 mm

Repetition accuracy

maximum 0.2 typical 0.1 mm

Finger position resolution

typical 0.1 mm

Total stroke (adjustable)

maximum 110 mm

Payload Form Fit

maximum 5 kg

Payload Force Fit

maximum 2 kg

Logistic data

Dimensions

213 x 149 x 36 mm

Weight

0.78 kg

Operating Conditions

Calculated MTBF (operating life)

minimun 30.000 Hours

Relative humidity (non-condensing)

maximum 95 %

Operating temperature

minimun 5 maximum 50 °C

Current consumption

minimun 70 maximum 600 mA

Power supply

minimun 20 maximum 25 typical 24 V

Storage temperature

maximum 60 °C

Downloads

Related posts

view all blogpostsIndustrial vs. collaborative robots: end-of arm tooling makes ...

If you’re looking into collaborative automation, EoAT is the key in optimizing your processes and growing your business with greater flexibility, higher output and ...

Innovative collaborative machine tending saves time in manufacturing

The recommended tools for machine tending are RG2 and RG6 dual grippers. These industrial grippers attach easily to the end of a robotic arm ...

The right way to start useful robotic automation

When implemented correctly, robotic automation can spur greater efficiency, deliver better results, lower costs and increase flexibility—for both SMEs and larger-scale manufacturing companies.

Diving into the concept of useful collaborative applications

Collaborative applications allow workers and robots to operate safely side by side due to the user-friendly nature, intuitive programming and safety features of EOAT-fitted ...